The food industry is one of the most dynamic sectors, constantly evolving to meet consumer demands for high-quality, safe, and affordable food. As the global population grows, so does the need for more efficient production and distribution systems. Among the technologies revolutionizing food production and safety, robotics and Artificial Intelligence (AI) stand out. These technologies are playing an increasingly critical role in improving food safety, quality control, and overall operational efficiency.

The Growing Need for Food Safety

Food safety is a priority for every segment of the food industry, from farms to production lines and even in retail and foodservice establishments. With the rise of foodborne illnesses and contamination concerns, ensuring food safety has become more challenging. Traditional methods of food safety management, while effective, are often time-consuming and prone to human error. This is where robotics and AI come in, offering solutions that help reduce risks and enhance the efficiency of food safety measures.

How Robotics Is Revolutionizing Food Safety

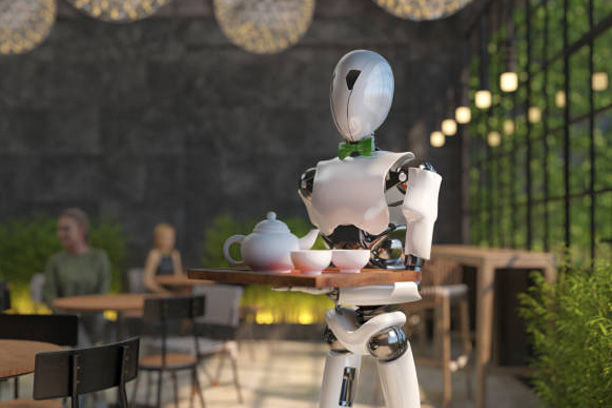

Robotics is increasingly being utilized in various stages of food production to ensure consistent quality and minimize contamination risks. Automated systems can work in environments where human presence is limited due to hygiene or safety concerns, such as in sterile production environments or areas with high contamination risks.

- Precision and Consistency in Food Handling

Robots can handle food items with precision, ensuring that every product is processed and packaged according to strict safety standards. They can inspect, sort, and package food with incredible accuracy, reducing the risk of contamination during processing. For example, robots in food processing plants can separate damaged or contaminated food items from those that meet quality standards. - Sanitation and Hygiene

Robots equipped with UV-C light technology or automated cleaning systems are now used for routine sanitation tasks. These robots are capable of disinfecting large-scale production environments, minimizing the risk of cross-contamination. They can also help maintain high hygiene standards by conducting frequent checks of equipment and surfaces. - Temperature Control and Monitoring

Robots can be equipped with temperature sensors to ensure that food products are stored and processed at the correct temperatures. This is crucial in preventing bacterial growth, which is one of the main causes of foodborne illnesses. AI-powered robots can also monitor temperature changes in real-time, allowing for immediate intervention when there is a deviation from set parameters.

AI’s Role in Enhancing Food Safety

Artificial Intelligence is playing a pivotal role in improving food safety by providing real-time analysis, predictive capabilities, and greater control over production processes. AI systems can process large amounts of data and identify patterns that would be impossible for humans to detect.

- Predictive Analytics for Quality Control

AI-powered systems can analyze data from various sources, such as sensors, cameras, and historical records, to predict potential risks in food production. These systems can identify patterns that lead to contamination or spoilage, allowing producers to take proactive steps before problems arise. This reduces food waste and ensures that only safe, high-quality products reach consumers. - Real-Time Monitoring and Alerts

AI-powered systems can continuously monitor food production environments and provide real-time feedback on food safety. By integrating sensors that measure temperature, humidity, air quality, and equipment status, AI systems can detect deviations from optimal conditions and automatically trigger alerts. This can help prevent contamination or spoilage before it occurs. - Traceability and Transparency

AI-driven blockchain technology is enabling greater traceability and transparency in the food supply chain. From farm to table, AI can track every step in the production process, allowing food safety issues to be traced back to their origin. This provides both producers and consumers with confidence that the food is safe and meets regulatory standards.

Benefits of Robotics and AI in Food Safety

- Improved Efficiency: Robotics and AI streamline operations, reducing the time spent on manual tasks, leading to faster production cycles and better resource management.

- Reduced Human Error: Automation minimizes human error, which is a common cause of food contamination and safety breaches.

- Enhanced Hygiene: Automated sanitation and hygiene checks ensure higher cleanliness standards, preventing cross-contamination risks.

- Cost Reduction: While the initial investment in robotics and AI may be significant, over time, these technologies can lead to cost savings through reduced waste, improved product quality, and fewer safety incidents.

The Future of Food Safety: A Collaborative Approach

As robotics and AI continue to evolve, they will work hand in hand with human expertise to create a more efficient, safe, and sustainable food industry. The combination of automation, data analytics, and human oversight will be essential in managing food safety risks while optimizing production processes.

The integration of these technologies offers vast potential for enhancing food safety at every level of production and distribution. With continued innovation, we can expect even greater advancements in food safety practices that ensure consumers have access to high-quality, safe food, all while reducing the environmental and economic impact of food production.

In conclusion, the role of robotics and AI in the food industry is transformative, providing solutions that not only improve food safety but also enhance overall operational efficiency and sustainability. As these technologies continue to advance, they will play an even more critical role in shaping the future of food safety.